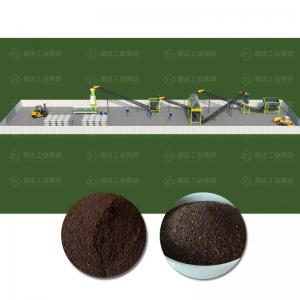

Organic Fertilizer Powder Production Line for Handling Poultry Manure and Municipal Waste

Organic fertilizer mainly involves fermenting and decomposing animal manure organic waste such as cow manure, sheep manure, pig manure, chicken manure, sludge, rice straw, and corn straw. The organic waste with a moisture content of about 30-35% is crushed and screened, and then mixed with binders (bentonite, humic acid) and other ingredients according to the ratio requirements in the ingredient mixing system Adding functional bacteria can produce bio organic fertilizers, while adding nitrogen, phosphorus, and potassium (with a total nutrient content of less than 15%) can produce organic and inorganic fertilizers. The ingredients are mixed and the thoroughly mixed materials are uniformly and continuously fed into the crusher by a belt conveyor. After passing through the crusher and screening machine, the finished products are transported by the belt to the finished product silo, measured and packaged by a computer quantitative packaging system, and stored in the warehouse.

What are the raw materials for organic fertilizer?

Animal manure: chicken manure, pig manure, cow manure, earthworm manure

Crop residues: corn stover, wheat straw, straw, leaves, weeds, peanut seedlings, soybean stalks, palm fiber, oil cake: peanut cake, soybean cake, cottonseed cake, rapeseed cake

Industrial waste: wine dregs, vinegar dregs, cassava dregs, sugar dregs, furfural dregs

Kitchen waste

Composting materials: kitchen waste, plant residues, lawn clippings, straw, wood chips and other organic waste, etc.

Seaweed and aquatic plants: rice seedlings, lotus seedlings, etc.

Food processing waste: fruit peels, fruit pomace, coffee grounds, etc.

Fish meal and fish bone meal

Humus soil

Municipal sludge

Humic acid: potassium humate, xanthate

If you have a better idea, or would like to do an experimental test as well, please contact us right away!

| Model | Capacity(t/h) | Feature |

| Organic drum granulation production line | 0.5-20t/h,1000-200000t/year | Raw material is power, add to 40% humidity,then make granules,dry granules. |

| Organic roller granulation production line | 0.5-20t/h,1000-200000t/year | Raw material is power, add to 40% humidity,then make granules,dry granules. |

| Organic granulation production line | 0.5-20t/h,1000-200000t/year | Raw material is power, add to 40% humidity,then make granules,dry granules. |

| Disc granulation production line | 0.5-20t/h,1000-200000t/year | Raw material is power, add to 40% humidity,then make granules,dry granules. |

The powdery organic fertilizer production line, like the granular organic fertilizer production line, uses animal manure to add crop auxiliary materials, which are processed into organic fertilizer through organic fertilizer equipment. Due to its simple process, less equipment required, and less investment, the cost of the powdery organic fertilizer production line can be recovered within a year. Many customers want to purchase a powdery organic fertilizer production line, and their main concern is the revenue of powdery organic fertilizer, The equipment required for the production line of powdered organic fertilizer includes an organic fertilizer flipper, a horizontal mixer, and a high humidity material crusher.

In the production line of powdered organic fertilizer, as the materials need to be crushed after fermentation, a crusher is needed. This machine has the same crushing effect on fermented organic fertilizer, sludge, biogas residue, coal gangue and other slag. The production capacity of the high humidity material crusher is 1-4 tons, and the feed moisture content is ≤ 40%. The power configuration and raw material moisture content of the production capacity meet the requirements of the powder organic fertilizer production line. Therefore, it is very suitable to match the high humidity material crusher with the powder organic fertilizer production line.

FAQ:

1..How should to do if I meet some trouble while using?

A:The English manual book and video will be provide for showing how to resolve the problems, if necessary, we will dispatch our engineer to your factory.

2. Do you provide the installation service afterordering your machines?

A:As for the single machine, we provide the users instruction and operation video.As for the production

line,we provide the professional construction drawing,and arrange the engineer guide the user install the machines.Help the user train the skilled workers.

3.Can we visit your factory to see some fertilizer plant with your machine?

A:We really give every customer a warm welcome to visit our factory,and we can take the customer to visit fertilizer plants with our equipment.

Animal manures fertilizer pellet production line /organic fertilizer granulator production line for sale , inquiry now:)